Blog

Precision Machined Components – Should You Repair Or Replace Them?

When it comes to manufacturing precision-machined components, choosing the highest quality materials and the most experienced engineers are a must. However, no matter how well the part is manufactured, it may eventually break down. A broken component puts a machine out of order, thus resulting in downtime which may be extremely costly. Should you opt for repairing the parts or manufacture new ones? At Woodley Engineering, we repair and replace all types of precision machined components. If you aren’t sure whether you need to repair or replace them, we can offer

Replacement, Reconfiguration & Repair Of Parts For Production Lines & Conveyor Systems

Finding new solutions for the replacement, reconfiguration, and repair of parts for production lines and conveyer systems may seem time-consuming. As surprising as it may be, the OEM option is not always the best one. The original equipment manufacturer will produces high-quality parts. However, the time it takes to do it may result in unexpected production line and conveyer system downtime. Meanwhile, the cost for small volumes may be high. At Woodley Engineering, we produce bespoke equipment parts which comply with the highest standards and manufacturer specifications. The numerous advantages

An Alternative To OEM Replacement Parts For Production Lines

Ordering a replacement part for your production line equipment should be straightforward. You call the original equipment manufacturer and place an order, right? Unfortunately, getting the replacement components with a good price and turnaround is not always easy. OEMs produce high-quality spare parts, but their focus is volume, not necessarily replacement parts. Large and busy companies aren’t always focused on fast delivery for spares since they don’t stake their reputation on speed. As a result, your production line may experience downtime when parts break down. What is the alternative? A third party manufacturer

5 Things To Look For When Choosing Precision Engineering Services

Are you looking for the highest-quality machine manufactured components for your equipment? Then you need reliable precision engineering services. What do you expect from such a company? When making a list of requirements, you may realise that the number of companies fitting your needs is limited. At Woodley Engineering, we know all the ins and outs of this business. We would like to share several things to look for when choosing precision engineering services. 1) Sufficient Experience Manufacturing of proper replacement parts, their repair and configuration don’t just rely on high-quality

Case Study: The Challenge Of Taking On A New Manufacturing Task

There are many ways we get involved with projects. Sometimes we are asked to look at ways of modifying existing parts to allow new functionality or operation outside of normal scope, sometimes we are asked to repair damaged components, and sometimes we are presented with a series of parts and are asked to replicate them. We would like to share some reflections on a recent project that we feel is revealing about the way we approach engineering challenges. The project was by no means straightforward or plain sailing; but the

Woodley Engineering: Production Line Specialists

n a competitive world, your business needs every advantage it can find, and as new equipment is developed, investing to remain at the cutting edge of your market is crucial. However, with even the most meticulously planned production line, an addition of a new machine can create challenges of all kinds that need fast solutions to enable you to maximise return on that investment as quickly as possible. Common Production Line Issues There are several issues you can run into, starting with the machinery itself. Integration of New Production Assets

OEM Or Aftermarket?

It’s a question you have probably asked yourself: which is better, OEM or aftermarket? Not so long ago, the answer was clear, but technology has changed things considerably, and today the question needs asking again. Advantages & Disadvantages Of OEM Solutions Starting out with OEM solutions, there are several obvious advantages. The first is material conformity; that is the materials will always comply perfectly with the original specifications. In a similar way, tolerances and finishes are always to the exact specifications of the originals parts. However, that perfect specification comes

Case Study – Parts For Production Line In The Consumer Healthcare Manufacturing Industry

Our team at Woodley Engineering bring vast experience to any project involving conveyor systems, with a successful track record behind us. This is why so many trust us with their critical production infrastructure. One such project we have been working on recently involves a new production facility for consumer healthcare products and packaging. The Brief Within the workspace there are two machines; a packaging machine and a cartonning machine, which need to be connected by a conveyor system to optimise output. However, there are some challenges faced here: the space

QUALITY PRECISION ENGINEERING OF COMPONENTS TO KEY INDUSTRIES

For many years we have been helping professional buyers and engineers meet their objectives by providing a reliable source of top quality precision machined components to exact customer specification. We are a key supplier of components to the following industries: Electrical Chemical Testing Nuclear Power Diamond Sorting & Assaying Oil, Gas & Heating Healthcare & Pharmaceutical Food & Agricultural We offer a good combination of traditional engineering skills but with the latest in CNC milling and turning machining capabilities. To discuss more about how we can assist your machining requirements,

Engineering in Reading, Slough, High Wycombe & Berkshire

Woodley Engineering offers a rare blend of up to the minute CNC machining technology and old fashioned skills. We can, of course, produce intricately precision machined parts on CNC machining centres, either as a one off or in multiples of many hundreds. Design, drawing and set up time accounts for a large proportion of the production costs on smaller quantities, so for the most cost effective solution, orders of a minimum of 10 are recommended unless a prototype is required pre-production. Alongside these capabilities, we also offer a highly skilled

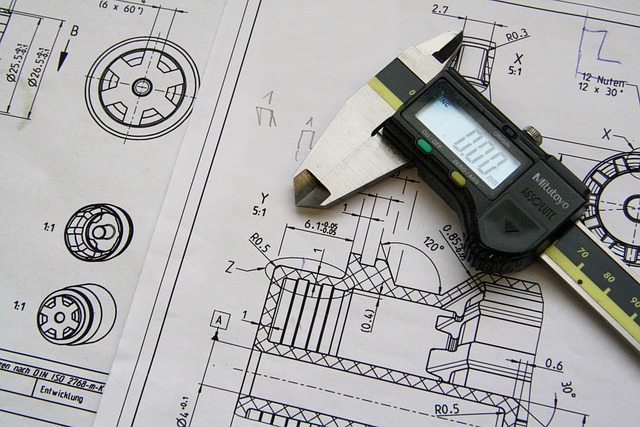

CNC Machinery and Manual Precision Machining

Most of our work involves making parts for our customers to use in their production machines. It is vital that these are produced to the exact specifications requested. Starting with the material, we ensure that the precise description is passed on to our suppliers so that we can make sure that products conform to the requirements. As orders are processed, the material description will be entered onto our database for comparison with the supplier’s delivery note. Our engineers will produce a drawing if none is supplied which will be submitted

Quality Control

Most of our work involves making parts for our customers to use in their production machines. It is vital that these are produced to the exact specifications requested. Starting with the material, we ensure that the precise description is passed on to our suppliers so that we can make sure that products conform to the requirements. As orders are processed, the material description will be entered onto our database for comparison with the supplier’s delivery note. Our engineers will produce a drawing if none is supplied which will be submitted