Equipment

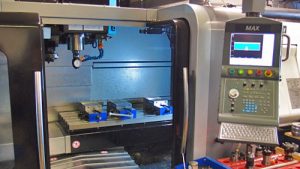

Milling

2014, Hurco VM20i 3-axis Vertical CNC Machining Centre Serial No. S20-1610234DAAAH. Software: AVG, NCPP, ISNC, Rigid Tap, TC OPTI, SFQ, Ultimotion, DXF, Ultipocket, Ramp Entry, 3D Mould, NC Merge, Swept Surface. X Travel 1,016mm, Y Travel 508mm, Z Travel 508mm, Spindle Nose to Table 102mm. Table size 1,168 x 508mm, Max Load 544kg. Max Spindle Speed 10,000RPM, Spindle Power 20hp, 15kw, Spindle Torque 102Nm, 450RPM. 20 Tool Carousel, Tool Type CAT 40, Max Tool Diameter 89mm, Max Tool Length 250mm, Max Tool Weight 6.8kg. Rapid Traverse per Minute X=24m, Y=24m,

View AllTurning

2012, Yamazaki Mazak Quick Turn Nexus 200M-2, Serial No 237004 Horizontal CNC Lathe, 3 Axis turning & milling, Mazatrol Matrix Nexus Control, 65mm Maximum Bar Dia, 380 mm Maximum Cutting Diameter, 675 mm Maximum Swing, 230 mm X Axis Travel, 538mm Z Axis Travel, 360,000 increments on C Axis @ 0.001 degrees, Programmable Tailstock, 8” Chuck, 3 Vertical and 1 Horizontal driven Tools for milling, 12 tool turret, Parts Catcher, Chip Conveyor. 2005, Yamazaki Mazak Quick Turn Nexus 200M, Horizontal CNC Lathe, Serial No 173214, 3 Axis turning & milling,

View AllGrinding and Linishing

Our Jones and Shipman 1400 Surface Grinder gives us the capability to produce fine sharp edges on hardened steel guillotine blades, to finish work to tolerances of within 1 thousandth of an inch on magentic steel plates and to refurbish damaged surfaces. Machined parts are polished on the linishing belt for a fine, accurate finish 2" Linisher for fine finishing

View AllWelding/Fabrication

Marshall “Dynabolt” MD300P TIG Welding Set, Aluminium, Stainless Steel & Alloy Steel Capability. Murex 160 MIG Welding Set Light Steel & Sheet Steel Fabrications with Spot-Welding Facility. 1 off Cutmaster Bulldog 200 Power Hacksaw with 200mm round/square capacity 1 off Meddings 260 Pull down Saw, Circular Blade The capacity for Light Fabrications is supported by our Oxy/Acetylene Cutting and Welding plant, a variety of Grinding and Linishing Equipment, as well as access to Power Bending & Guillotine Equipment.

View AllFitting And Assembly

We offer Comprehensive Assembly Facilities supported by a host of small tools and equipment Including Bench and Pillar Drills, a Treadle Guillotine, Manual Rollers, a Broaching Press, a 10 and a 20 tonne Floor Press and for lifting assistance a 250 kg SWL Pelloby Power Hoist mounted on a Jib Crane Compressed air supplied by an Atlas Copco GX5 Single Stage Screw Air Compressor is piped throughout the workshop

View All